Biogas

Biogas is a combustible gas consisting of methane, carbon dioxide, small amounts of other gases and trace elements.

Biogas is produced as a by-product of the anaerobic digestion of organic matter by micro-organisms. On a commercial level, various types of this organic matter known as feedstock can be used for the production of biogas. These include-

• Animal manure and slurry

• Agricultural residues and by-products of crop production

• Digestible organic wastes from the food production industry (vegetable and animal origin)

• The organic part of municipal waste and from catering (vegetable and animal origin)

• Sewage sludge

• Dedicated energy crops (e.g. maize, miscanthus, sorghum, clover).

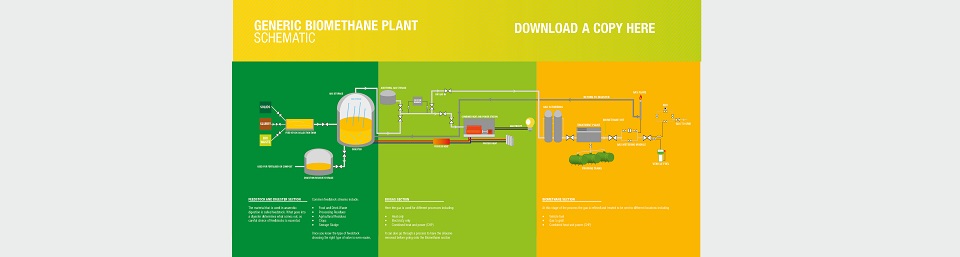

Anaerobic Digestion is the microbiological process of the decomposition of organic matter, in the absence of oxygen. It is common to many natural environments and largely applied today to produce biogas in air proof reactor tanks, commonly named digesters. A wide range of micro-organisms are involved in the anaerobic process which has two main end products; biogas and digestate, the product remaining from the gas removal process. Digestion is carried out in large tanks containing the feedstock and micro-organisms and is where the gas produced is at low pressure.

Once biogas has been “cleaned up” it can be utilised on site in a Combined Heat and Power (CHP) Plant or treated further to become pipeline quality biomethane and injected into the national gas grid.

Biomethane

Biogas becomes biomethane when it is upgraded to pipeline quality gas. It is identical in property to natural gas. Biogas starts with 60 - 70% methane (CH4) but contains some unwanted additions such as hydrogen sulphide (H2S), carbon dioxide (CO2), water and possibly siloxanes (synthetic silicone derivatives), dependent on the feedstock.

To meet UK gas pipeline specifications and to be injected into the national gas grid for general use, it must go through a number of processes which removes these unwanted compounds producing an almost pure (98%) methane gas.

If the calorific value of the gas falls below a minimum threshold, propane can be added to bring it up to acceptable levels. The resulting biomethane then can be injected into the gas network or compressed for use in natural gas vehicles.

It is important when choosing valves and fittings for use on a biogas plant that the correct products are chosen for each particular section of the process. Overall in the connecting pipeline assemblies you could have a requirement for knife gate, wedge gate, resilient seated, butterfly, ball and non-return valves depending on the process. To select the correct valve for the application the following general points should be taken into consideration:

• Carbon steel should not be used on biogas due to the H²S, content. It is recommended for these applications that stainless steel be used for valve internals and the valve bodies be either cast/ductile iron or stainless steel.

• Consider the level of H²S when choosing valve sealing materials. Viton is recommended over nitrile if the H²S content is above 200 ppm.

• Consider the pressure drop through the valve. Use clear bore wherever possible. Consider that butterfly valves have line restriction.

• Knife gates are recommended if the feedstock is more than 10% solids.