Coal Seam, Shale Gas and Abandoned Mine Gases

Coal Seam Gas is the name given to any naturally occurring gas trapped in underground coal seams by water and ground pressure.

The most common gas found in coal seams is methane which was formed millions of years ago as part of the breakdown and compression of peat to form coal. The gas lies in the open fractures within the coal seam and surrounding areas and also inside pores within the coal. This natural gas is almost pure methane, typically over 97%.

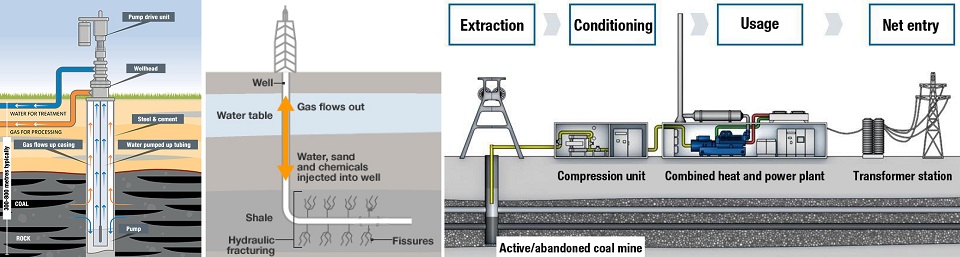

Coal seam gas is extracted by drilling a well vertically through rock strata until reaching the coal seam, at which point the well may also be drilled out horizontally to increase access to the methane gas.

Hydraulic fracturing, more commonly known as “fracking” is used to stimulate and accelerate the flow of coal seam gas. The process involves high pressured injection of sand, water and chemicals into the coal seam gas well. The injection causes fractures in the coal seam allowing the gas to flow to the surface of the well where it can be collected.

A significant amount of water can also be liberated as part of the gas extraction process which varies in quality, can be treated and reused in a variety of ways such as irrigation or to top-up local water supplies.

Shale Gas

Shale gas is natural gas which is held in fractures, pore spaces and absorbed into the organic material of shale. Shale gas is generally liberated through the fracking technique.

This raw natural gas principally consists of methane from different sources and can have different impurities such as condensates, water, carbon dioxide and hydrogen sulphide that must be removed before the gas can be transported into pipelines and sent to market. In order to achieve this there is a requirement for a “scrubbing process” similar to that used for biomethane.

Abandoned mines methane (AMM) can be recovered from disused coal mines. AMM projects produce energy (thermal and electrical) with the added bonus of reducing atmospheric emissions of methane. Methane is a potent greenhouse gas and huge amounts of methane will escape from the mine for years to come following closure. Sealed abandoned mines offer an excellent opportunity for methane extraction, especially if recovery takes place quickly after the mines closure. AMM provides a good source of medium to high quality methane.

The main constituents of mines gas are methane (CH4) oxygen (02), nitrogen (N2), carbon dioxide (CO2). If blasting operations are used in the mine, then carbon monoxide (CO) can occur in large quantities. In addition, hydrogen sulphide can be present. The concentration of CH4 depends upon the quality and depth of the coal seam: in general, the higher the energy values of the coal and the deeper the coal bed, the more CH4 occurs. The methane content can range from 60-80%.

Abandoned mines gas is generally used on the same site as the gas extraction to power a combined heat and power (CHP) plant to produce electricity which is then sent to the grid for a feed in tariff.

Oil Shale Gas

Oil shale gas is a synthetic gas mixture (syngas) produced as a by-product of oil shale pyrolysis. In this process, oil shale is heated in the absence of oxygen until its kerogen decomposes into condensable shale oil vapours and non-condensable combustible oil shale gas. Oil vapours and oil shale gas are then

collected and cooled, causing the shale oil to condense and be collected. Although often referred to as shale gas, oil shale gas differs from the natural gas produced from shale.

Typical components of oil shale gas are usually methane, hydrogen, carbon monoxide, carbon dioxide, nitrogen, and different hydrocarbons like ethylene. It may also consist of hydrogen sulphide and other impurities, which need to be removed again through scrubbing processes.