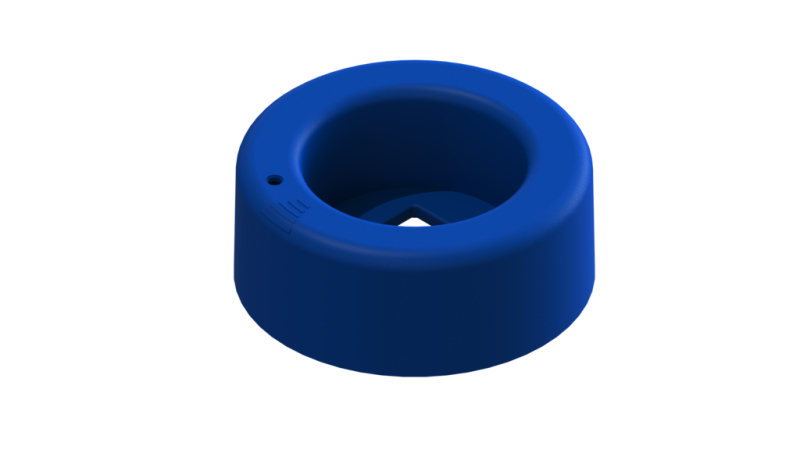

AVK RESILIENT SEATED GATE VALVE, PN16

Smart Water. Product upgraded - see 21/35-002

Anthony Whittam

Head of Smart Water and Pressure Management

Resilient seated gate valve to BS EN 1074-2 / BS 5163-1 for water and waste water. Temperature range: -10° C to +70° C. 10% solid matter. Insulation essential for temperatures of 0° C and below. Maximum Working pressure: 16 Bar.

The 21/50-009 Smart Water resilient seat, wedge gate valve for isolation purposes. These valves are equipped with a VIDI Positioner, a smart device for indicating the position of gate valves and whether it is open, close, or any percentage in between and transmits the data wirelessly. Based on the data provided, water utilities can optimise the operation of the water distribution network, asset auditing, efficiently lower water loss.

| Variant 21/50-009 | |

|---|---|

| Connection: | Flanged |

| Material: | Ductile Iron |

| PN: | PN 16 |

Features

- Communication: NB-IoT (band 8 & 20) or LoRa® (868MHz).

- Detects the position of the valve and transmits data and alerts to the VIDI Cloud or a third-party software.

- Fitted with an AVK status indicator - see product reference 3004/100-001

- Cap top as standard.

- Ductile iron wedge, fully vulcanized with EPDM rubber.

- O-ring stem seals replaceable under pressure.

- Fully corrosion resistant construction.

- Blue fusion bonded epoxy coating, in accordance with WIS 4-52-01.

- Body, bonnet and gland bolts sealed with hot melt.

- Lifting bars.

- Embodied Carbon Data available upon request.

- Options:

- DN80-200 see 21/35-002

- PN10 flange drilling

- Version available for salt laden environments see 21/58-001

- Safety Note:

- The valves now accomodate lifting bars for the safe handling of valves. These lifting bars are rated to the weight of the bare valve and stem cap (where fitted) only and should not be utilised if the valve is fitted with pipe, mechanical pipe joints, gearboxes, actuators or any other external fitment. AVK will not accept any responsibility for loss or damage if the lifting bars are not used in strict accordance with this guidance.

Downloads

Components

| 1. | Stem Cap | Cast iron GJL-250 |

| 2. | Screw | Steel 8.8 |

| 3. | Plastic | |

| 4. | Wiper ring | NBR rubber |

| 5. | Base | Plastic |

| 6. | O-ring | NBR rubber |

| 7. | Bearing | |

| 8. | O-ring | NBR rubber |

| 9. | Thrust collar | DZR brass |

| 10. | O-ring | NBR rubber |

| 11. | Stem | Stainless steel 1.4021 |

| 12. | Bolt | Steel 8.8 |

| 13. | Wedge nut | Brass CW626N |

| 14. | Wedge | EPDM |

| 15. | Wedge core | Ductile Iron GJS-500-7 |

| 16. | Body | Ductile Iron GJS-500-7 |

| 17. | Hot melt glue | |

| 18. | Gland | Ductile Iron GJS-500-7 |

| 19. | Bolt | Steel 8.8 |

| 20. | Bonnet | Ductile Iron GJS-500-7 |

| 21. | Gasket | EPDM |

| 22. | Wedge shoe |

Test/Approvals

- Approved according to WRAS

- Drinking Water Inspectorate Regulation 31 compliant

Standards

- Designed according to BS EN 1074 -1 and 2

- Face to face according to EN 558 Table 2 Basic Series 3

- Standard flange drilling to EN1092 (ISO 7005-2), PN 16