AVK SWING CHECK VALVE WITH LEVER AND WEIGHT, PN 16, DN350-600

Aluminium bronze seated BS body, metal seated disc, WRAS approved EPDM rubber

Anthony Whittam

Network Water Specialist

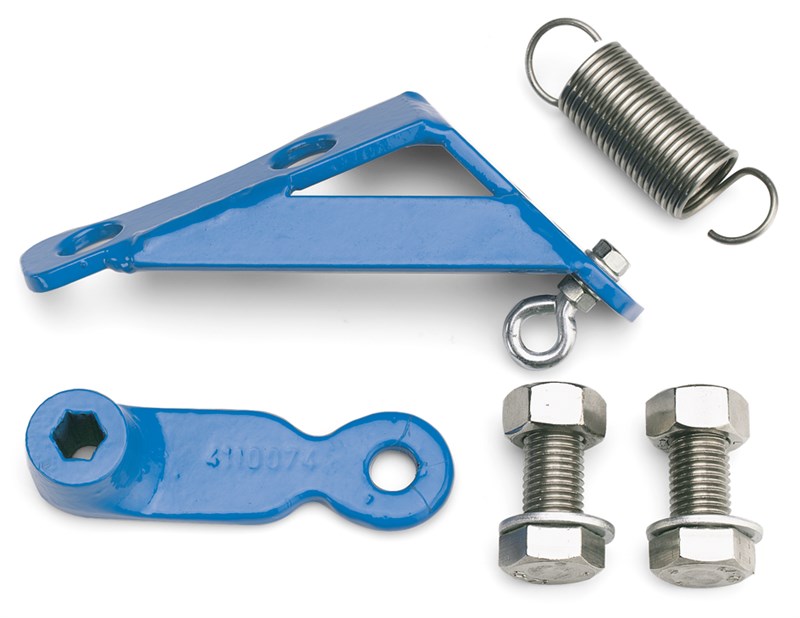

Metal seated swing check valve lever and weight kit for drinking water and neutral liquids to max. 70° C

AVK series 41 swing check valves come with both metal and resilient seats. Installed in pumping applications to prevent back flow they can be used for drinking water as well as waste water. The disc is connected to the shaft via a flexible bush that allows disc and valve seat to adjust exactly. All interior parts are stainless steel or coated with drinking water approved epoxy or EPDM. The series 41 valves are available with either closed bushings or protruding shaft end where a lever with a weight or a spring can be fitted to mitigate pressure surges.

| Variant 41/36-004 | |

|---|---|

| Connection: | Flanged |

| Material: | Ductile Iron |

| DN: | DN350 - DN600 |

| PN: | PN 16 |

Features

-

Clear way and full bore for low head loss and easy pig-cleaning

-

Metal seat in high strength alu-bronze

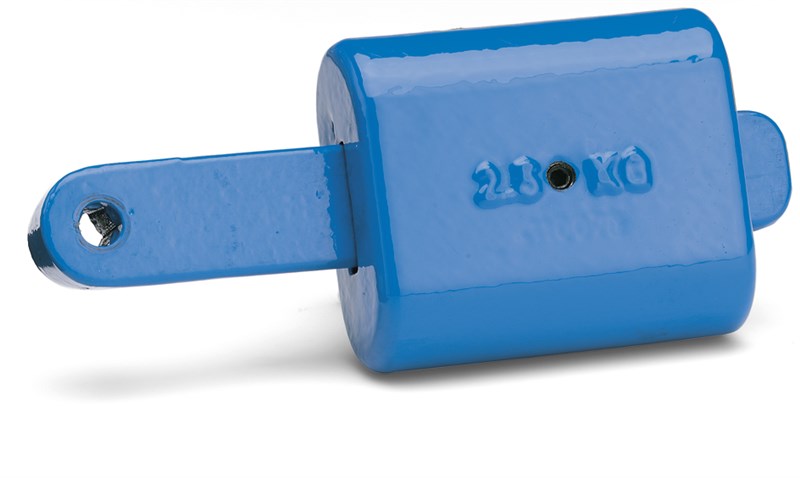

-

Shaft in 1.4404 (AISI 316L) acid resistant stainless steel fitted in the bonnet allows for easy maintenance without removing valve from pipeline

-

Position indicating lever with an adjustable weight that aids the disc in closing quickly to reduce water hammer, guard on lever mechanism

-

Hinge of ductile iron coated with drinking water approved epoxy, firmly tightened around the shaft to eliminate play

-

Bonnet gasket lying in a groove between bonnet and body prevents blow-out

-

All seals and coatings with contact to the fluid are approved for drinking water - coating is blue, 300µm fusion bonded epoxy

-

Disc mounted in a flexible rubber bushing which allows it to tilt slightly in all directions and adjust exactly to the valve seat

-

Bosses on each side of the valve seat allow for installation of pressure gauge, by-pass, etc.

-

WRAS approved product

Downloads

Reference nos. and dimensions:

| Ref. no. | DN mm |

Flange drillling |

L mm |

H mm |

H3 mm |

W mm |

W1 mm |

Theoretical weight/kg |

|---|---|---|---|---|---|---|---|---|

| 41-350-36-0180166 | 350 | PN16 | 800 | 673 | 943 | 794 | 499 | 269 |

| 41-400-36-0180166 | 400 | PN16 | 900 | 717 | 1012 | 864 | 539 | 358 |

| 41-600-36-0180166 | 600 | PN16 | 1300 | 947 | 1377 | 1110 | 663 | 869 |

Components

| 1. | Body | Ductile Iron GJS-500-7 |

| 2. | Washer | Stainless steel A4 |

| 3. | Nut | Stainless steel A4 |

| 4. | Stud bolt | Stainless steel A4 |

| 5. | Face ring | Alu-bronze CC331G (AB1) |

| 6. | Seat ring | Alu-bronze CC331G (AB1) |

| 7. | Bonnet | Ductile Iron GJS-500-7 |

| 8. | Bolt | Stainless steel A4 |

| 9. | O-cord | EPDM |

| 10. | Bolt | Stainless steel A4 |

| 11. | Washer | Stainless steel A4 |

| 12. | Nut | Stainless steel A4 |

| 13. | Spacer | PA |

| 14. | Guide bracket | Carbon steel |

| 15. | Bolt | Stainless steel A4 |

| 16. | Bolt | Stainless steel A4 |

| 17. | Weight | Ductile Iron GJS-500-7 |

| 18. | Guard back plate | ABS |

| 19. | Washer | Stainless steel A4 |

| 20. | Bolt | Stainless steel A4 |

| 21. | Spacer washer | PA |

| 22. | Guard front plate | ABS |

| 23. | Bolt | Stainless steel A4 |

| 24. | Washer | Stainless steel A4 |

| 25. | Lever | Ductile Iron GJS-500-7 |

| 26. | O-ring | EPDM |

| 27. | Bushing, open | Brass CW602N (CZ132) |

| 28. | O-ring | EPDM |

| 29. | Gasket | PA |

| 30. | Air plug | Stainless steel |

| 31. | Shaft | Stainless steel 1.4404 (316L) |

| 32. | Connector | Stainless steel 1.4408 |

| 33. | Spacer | Stainless Steel 1.4401 (316) |

| 34. | O-ring | EPDM |

| 35. | Bushing, closed | Brass CW602N (CZ132) |

| 36. | Guide bush | EPDM |

| 37. | Washer | Stainless steel A4 |

| 38. | Split pin | Stainless steel A4 |

| 39. | Castle nut | Stainless steel A4 |

| 40. | Stud bolt | Stainless steel A4 |

| 41. | Hinge arm | Ductile Iron GJS-500-7 |

| 42. | Disc | Ductile Iron GJS-500-7 |

| 43. | Protective bush | EPDM |

| 44. | Washer | Stainless Steel 1.4401 (316) |

| 45. | Bolt | Stainless steel A4 |

| 46. | Nut | Stainless steel A4 |

| 47. | Washer | Stainless steel A4 |

| 48. | Bracket | Stainless steel 316 |

| 49. | Set screw | Stainless steel A4 |

| 50. | Nut | Stainless steel A4 |

| 51. | Bolt | Stainless steel A4 |

Test/Approvals

- Hydraulic test according to EN 1074-1 / EN 12266 |

- Seat: 1.1 x PN. Body: 1.5 x PN.

Standards

- Designed according to EN 1074 - 3

- Face to face according to EN 558 Table 2 Basic Series 48

- Standard flange drilling to EN1092 (ISO 7005-2), PN 16

- WIMES 8.09 Compliant

- Drinking Water Inspectorate Regulation 31 compliant